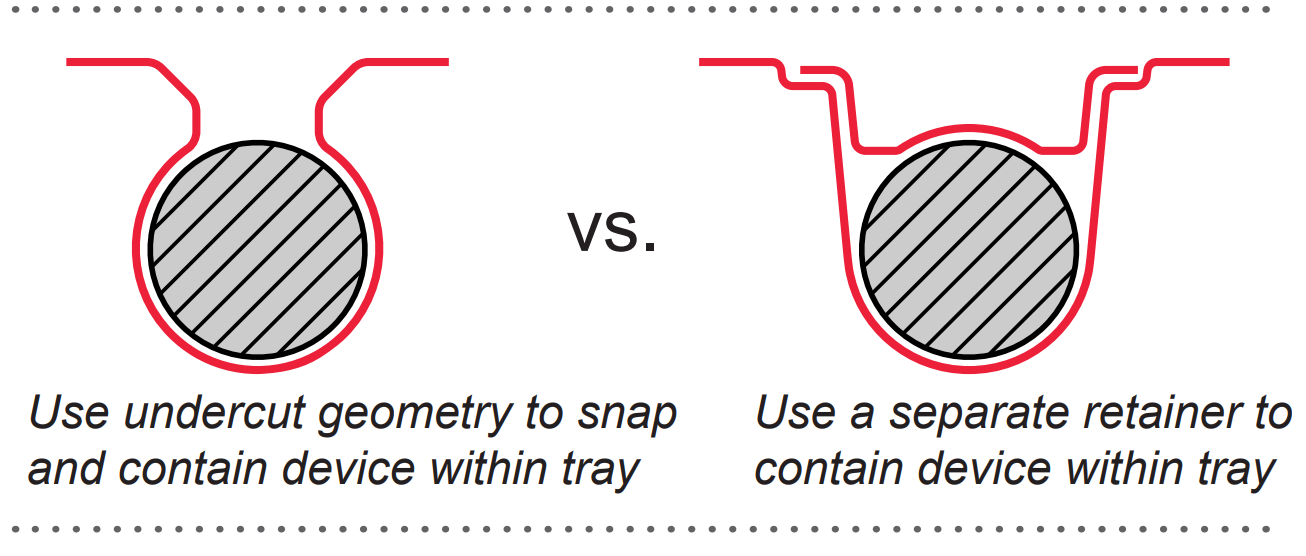

Often, thermoformed trays that hold medical devices are designed with a snap fit that uses undercut geometry to contain the device. But, based on feedback from nursing panels across the nation, this type of packaging can be cumbersome when ejecting products in a sterile, surgical field.

“When you snap in a device, it immediately causes ergonomic challenges for the end user,” says Chris Bladl, VP of Product Development. “Prent promotes using retainers because the non-barrier component of the packaging contains the majority of the complex geometry required for product retention. From a design perspective, the complexity can be in the retainer and not affect the sterile barrier.”

The benefits of using a retainer include:

* No stress on the device or thermoform as the device simply lays into its cavity

* Ideal for delicate, fragile, small or small-diameter devices

* Easy loading/unloading of the device

* No thin areas or denest height increases

* Retainers offer an extra layer of protection between the device and lidstock

Additionally, if the retainer is not subject to the same specifications as the tray, the retainer can have more challenging geometry to form to do the bulk of the work,” says Senior Designer Jason Erickson. “This allows for a simpler, easier-to-form thermoform that can result in a more robust, thicker tray.”

One of the deterrents for customers could be that a retainer requires an extra thermoform to purchase and manage, according to Erickson. However, the advantages of a retainer justify the extra cost, says Bladl. And, a new FDA standard that will require user feedback on medical device packages before releasing them, could encourage more customers to consider moving to a retainer in 2021.

To find out if a retainer is right for your product, please email sales@prent.com.